A while back, I was getting my tailwheel endorsement. After a morning of touch-and-goes on various grass strips, my instructor and I stopped at a little airport southwest of Fort Worth, Texas, to get some fuel.

As we were making conversation, he asked me about how many hours of flight time I had at the moment. At that point I had somewhere around 300 hours under my belt.

He warned me that, in his view, 300 hours can be a dangerous milestone. Pilots have enough experience at 300 hours, he said, that they should know what they’re doing and can be extremely competent. Where the danger is, he told me, is that at 300 hours most pilots have yet to see something big go wrong.

This lulls them into a state of comfortable overconfidence. Perhaps a similar risk might exist for rusty pilots—especially ones with significant previous experience.

The instructor told me a story about a former student who made a fuel stop, much like we were doing. The student, who the instructor mentioned had been among his best, had around 300 hours himself. He was usually diligent about checklist usage, but since he had already executed his preflight just a couple of hours ago and was only making a quick fuel stop, he didn’t think to do any checks before closing the gas caps and starting up.

It occurred to him while taxiing that he forgot to sump the fuel, but he was already pulling up to the runway. He had never seen anything in the fuel before and had already been flying for a couple of hours with no problems. He figured it would be all right to save some time and skip that step, just this once.

He took the runway and pushed in the throttle. Airspeed alive. He gently pulled back on the yoke as he gained airspeed and began to climb.

Things looked normal, for a moment. Then came engine roughness.

Roughness gave way to sputtering. Sputtering turned to the eery sound of silence, apart only from the wind outside the cockpit.

Although he was able to walk away from a safe off-field landing, his airplane did not survive. Though they say any landing you can walk away from is a good one, all too many like this could have been avoided altogether.

Situations like this are why good flight instructors everywhere drill thorough preflight inspections into their students’ heads from day one. These checks, often involving a combination of visual and functional assessments, are not just routine—they are lifesaving. Pilots returning to the cockpit need to ensure they do preflight inspections properly, thoroughly, and every time they fly.

The Importance of Preflight Inspections

Safety: It’s a nonnegotiable priority

Safe flight begins on the ground. Preflight inspections aim to find and eliminate risks that could compromise flight safety. They help detect mechanical failures— worn-out brake pads or loose bolts, for example—that could escalate into in-flight emergencies.

Preflight checks ensure the aircraft has the planned level of fuel and oil to accomplish the mission at hand and that these are free of impurities. Lights, instruments, and radios are tested to ensure we can confidently navigate, communicate, and be seen by others. At their core, these checks help pilots ensure they are prepared for whatever lies ahead during the flight.

We should get to a point where preflight check items are second nature, but we should still conduct these inspections with a checklist in hand. Since human error is a leading cause of aviation accidents, adhering to a systematic checklist during our preflight routine (and throughout every phase of flight, for that matter) helps pilots minimize the risk of overlooking essential matters.

Good preflight inspections can also alert owners to potential longer-term maintenance needs that they can plan for, leading to better and more convenient maintenance all around. Well-maintained airplanes tend to operate more efficiently and, while maintenance usually comes with certain expenses, preventative maintenance is always cheaper than waiting for problems to get bigger. This translates to cost savings for operators and less stress for pilots.

Best Practices for Preflight Inspections

The human factor: It’s a pilot’s responsibility

The safety of any flight is in the hands of the pilot in command (PIC). If you plan to return to the cockpit, then that, of course, means that you are taking on that weighty burden.

Beyond best practice, or even safety considerations (though that’s always the top concern), good preflight inspections help you limit some of the liability that comes with flying. It can admittedly be easy to get into the habit of going through the motions during an inspection without really doing what it takes to inspect the aircraft, though.

Human factors play a role here, too. Just as pilots need to evaluate their own fitness to fly, so should they also be conscious of their fitness and ability to conduct quality preflight inspections. If you are not up to the task of conducting a thorough preflight inspection, you probably are not up to flying that day either.

The inspection process

Walkaround inspection: In-flight safety begins on the ground. Visually examine your aircraft’s exterior before every flight to verify the condition of your airplane’s fuselage, wings, control surfaces, propeller, and landing gear. Keep a sharp eye out for damage, leaks, or obstructions to the engine, exhaust, pitot tube, or static port. Make sure everything that should move does and that everything that should not move, well, doesn’t. Pay attention also to tires, ensuring they are properly inflated and free of major wear. Above all else, follow your aircraft’s specific checklist. It may include items unique to it.

The walkaround should also include a few basic engine-related checks, including verification of engine oil levels, as well as close inspection for potential fuel or oil leaks. Through my years of flying older flight club planes, I’ve certainly run into both kinds of leaks on more than one occasion. I have horror stories I could tell about a particular Cessna 172 from the 1960s, if we had more time. Switch on the electrical system as well to verify proper function as well. The fuel quality and quantity should also be confirmed to match the planned flight’s requirements.

Take a minute to verify that the aircraft has the proper paperwork on board (remember the ARROW acronym?). Be sure to verify maintenance logs as well to ensure all required inspections are up to date. If the plane is not yours, the owner should make these available to you, often either digitally through whatever platform you use to book the plane or by leaving scanned copies of the logs onboard the aircraft.

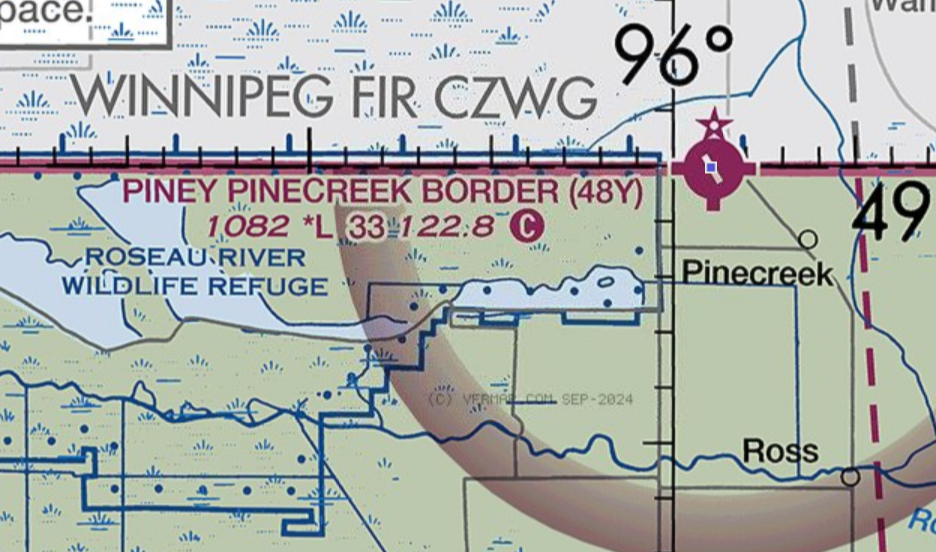

Run-up checks: Don’t forget that preflight inspections do not end once you’ve started up the plane. Listen to the radio for a moment to ensure proper functioning, and key up the mic to announce your intentions. As you start moving, verify that brakes are working properly, the magnetic compass and heading indicator are working well, and the turn coordinator moves when turning during taxi. Verify as well that the horizon is properly set on your attitude indicator and remains in the proper place as you move about the tarmac. This may also be a good time to perform any preflight inspections on advanced, flight-specific equipment, like an oxygen system you might be bringing along should the planned flight require it.

Before takeoff, be sure to stop off in the run-up area to perform your final preflight engine run-up checklist. This will look a bit different for every aircraft but generally will involve setting the brakes while throttling up to a specified level. While the engine is throttled up, check your various flight, engine, and electrical instruments to make sure readings are normal and within specified ranges. Assuming you are in a piston-driven airplane, perform mag checks and verify that rpm drops are within a normal range. If anything is out of the ordinary, the time to catch it is while you are still safely on the ground, so don’t rush the process. This is the ideal time to catch issues in a controlled environment rather than at several thousand feet above the ground.

Utilizing checklists

Checklists are invaluable tools in aviation. They ensure consistency, accuracy, and completeness in the inspection process. Several types of checklists can enhance a pilot’s workflow:

- Flow checklists: Follow the natural flow of the cockpit for quick and intuitive checks.

- Decision checklists: Aid in making informed choices during preflight and emergencies.

- Emergency checklists: Focus on handling unexpected situations efficiently.

Advanced Techniques and Technologies

Preflight inspection software

In addition to physical checklists like those available in the POH or from a third party such as Sporty’s Pilot Shop, EFBs offer an additional way to access your checklists. Tools such as ForeFlight provide pilots a way to keep their checklists on hand and organized while also providing capabilities such as automated reminders, photo documentation, and real-time updates.

Practical Advice for Rusty Pilots

Familiarity breeds confidence, and consistent, thorough preflight inspections provide wonderful opportunities to enhance familiarity with your airplane.

That said, do not let familiarity lead to laziness. The more frequently you perform detailed inspections—which should be before every flight, to be clear—the more intuitive and thorough your process ought to become. Consider pairing up with a more experienced pilot or with a flight instructor for your first few flights after a hiatus to double-check your work and discuss best practices. As your comfort level grows, challenge yourself to make your checks ever more thorough, avoiding any temptation to glance over or speed through inspection checklist items.

Preflight inspections are more than a checklist. They are fundamental to a pilot’s commitment to safety and opportunities to reconnect with the aircraft. Embrace the process, adopt best practices, and leverage advanced technologies to elevate your safety and efficiency.

The skies await, but the groundwork—both literal and figurative—begins with you.

FAQ

What is the purpose of a preflight inspection?

Preflight inspections help pilots verify the condition and airworthiness of their aircraft prior to flight. They usually involve a visual inspection of the aircraft’s exterior, checks for leaks, blockages, or damage to important components or systems, and verification of things such as oil and fuel levels.

What is the procedure of preflight inspection?

Preflight inspections are usually conducted in accordance with a checklist provided in an aircraft’s Pilot’s Operating Handbook, which might be supplemented with additional items deemed important by the pilot or aircraft owner.

Who does the preflight check?

Although aircraft owners and operators are responsible for maintaining their aircraft, it is ultimately the pilot who must check and verify that the aircraft is in a safe and airworthy condition prior to every flight.

The post Preflight Inspections: A Rusty Pilot’s Guide Back to Safety appeared first on FLYING Magazine.